Repair service

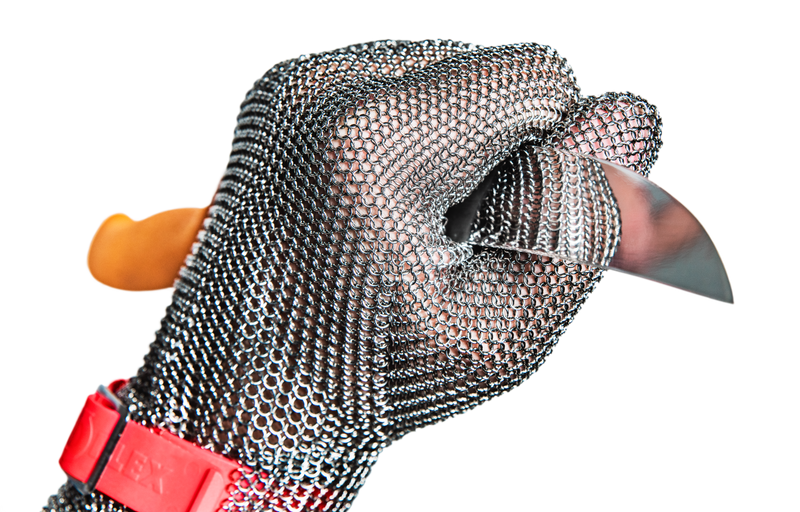

For more than 35 years, we have been repairing all types puncture and cut protection items made out of metal ring mesh. As far as possible, we only use original spare parts from the individual manufacturers, as this is the only way to ensure repair in accordance with existing standards. However, we ask for your understanding that we can not repair any Asian products for safety and warranty reasons.

We guarantee a professional replacement of your puncture-resistant products. If we also need to get your glove or apron back in shape, send your items carriage free to our address. Only clean items and, for this purpose, clean gloves, aprons and boleros, can be repaired. For large contaminants, a cleaning fee will be charged for the additional effort.

We will repair and return your goods within 8-10 working days.